Click HERE to see the PDF

General Specifications

Voltage: 100-550V

Current: up to 4500A

Circuits: up to 16

Network: Coax

Accuracy: +1% FS*

Input Power Supply: 3-phase, 50/60 Hz

[bs_well size=”sm”][/bs_well]

Overview

Available in a wide range of currents and voltages, the CDN is an economical solution for high voltage charge/discharge formation of stationary and industrial VRLA batteries and tank formation of automotive and industrial plates.

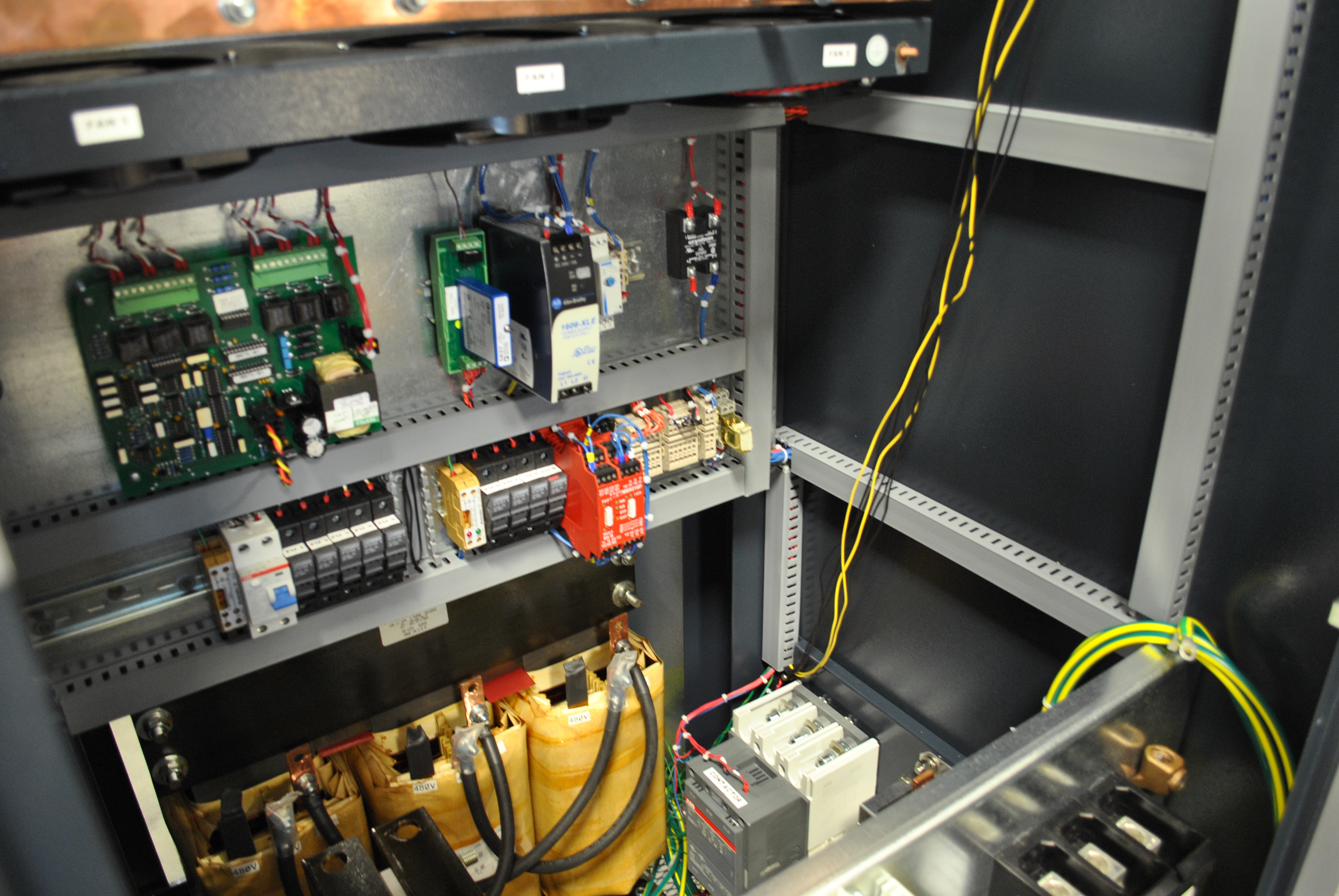

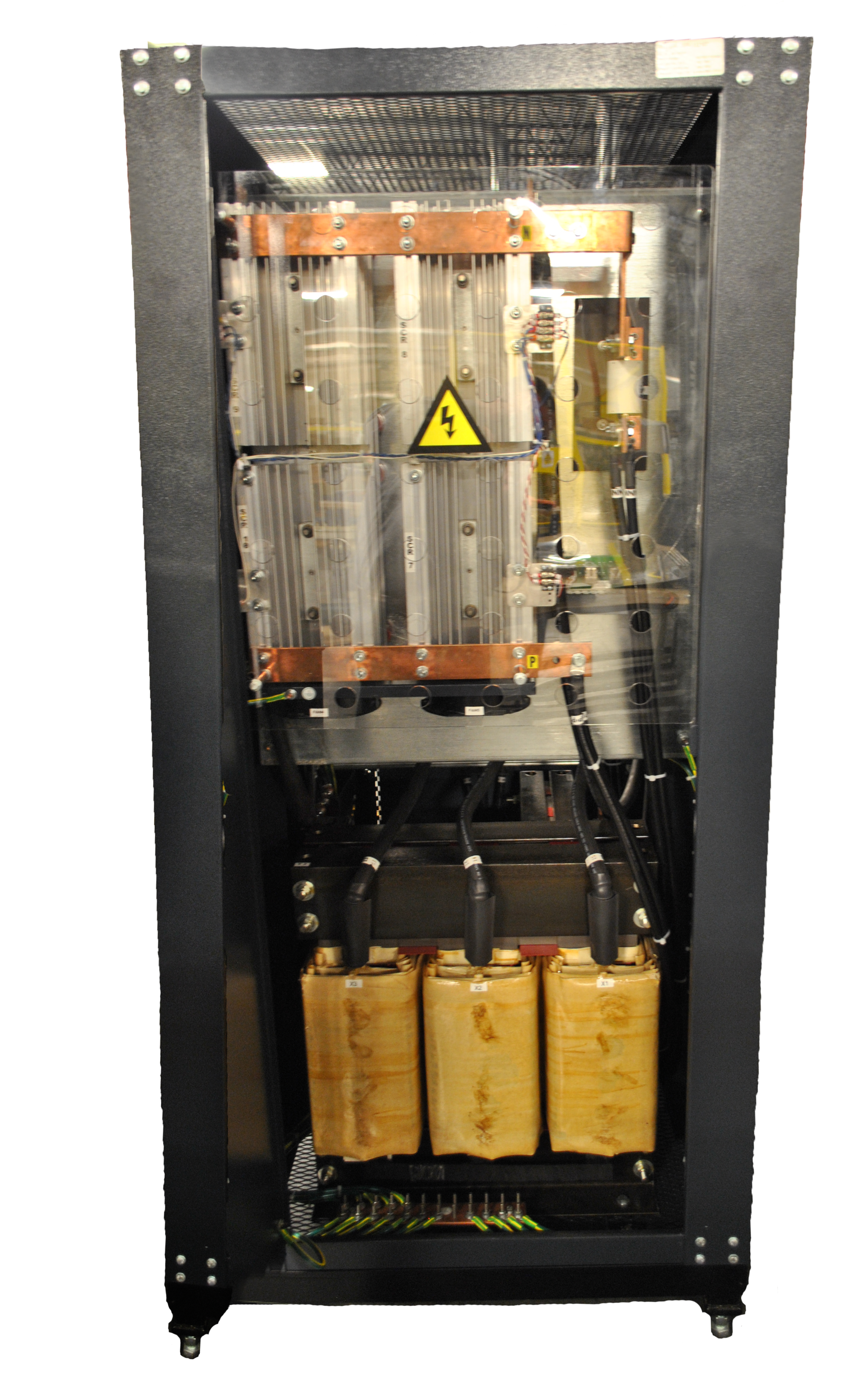

Using Bitrode’s three phase silicon-controlled rectifier, multiple circuits can be packaged in a single cabinet for low cost applications. In discharge, a three phase bridge discharges the DC energy back to the AC power line. This feature turns discharge energy into electrical power instead of heat, reducing stress on equipment and on the production formation environment.