Click HERE to download the datasheet PDF

General Specifications

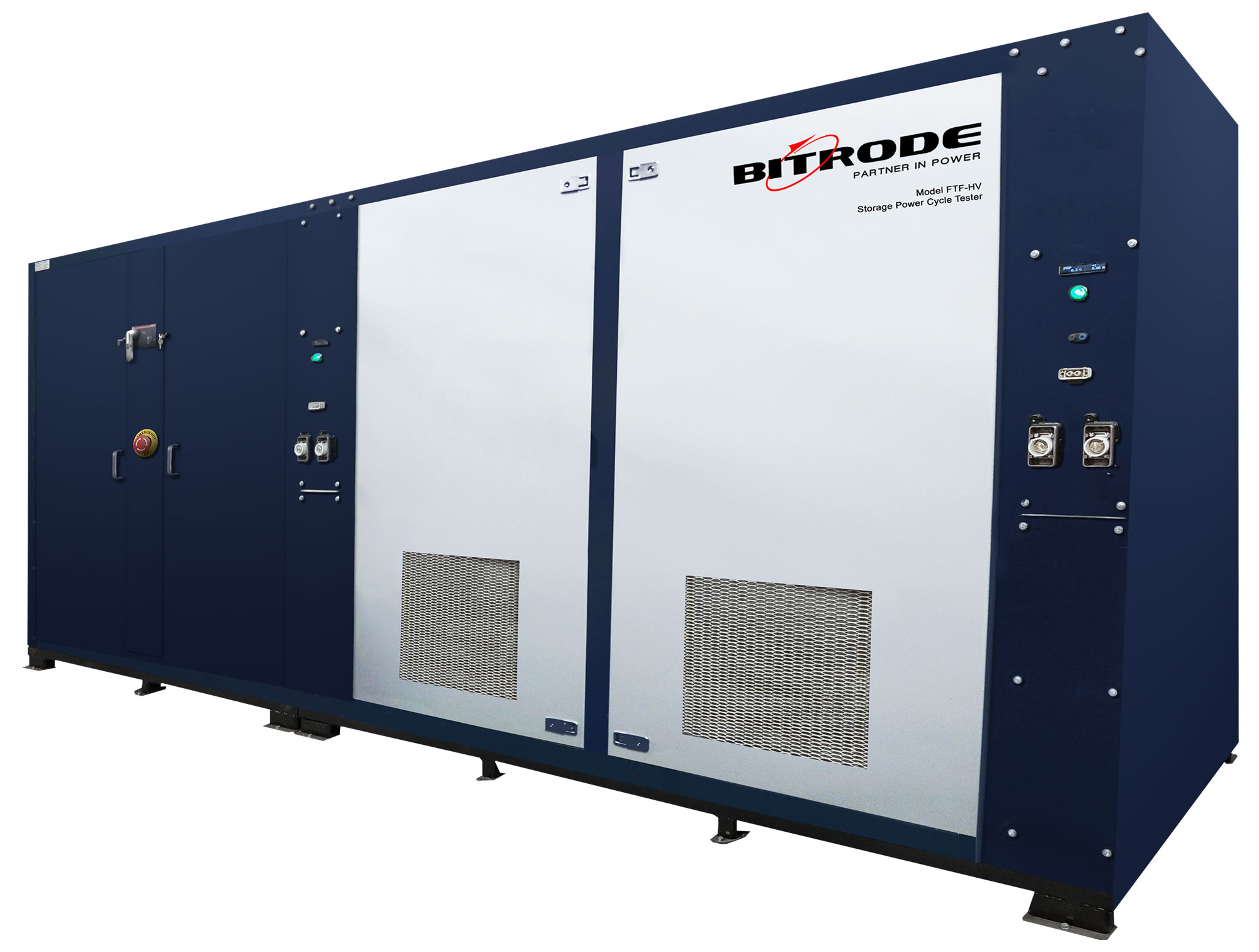

Number of Circuits: 2 (Max 4)

Voltage Configurations: 100-1500VDC

Max Current: 600/1200A | 1200/2400A

Max Power: 450KW | 900KW

Accuracy: Voltage – 0.1% of FS | Current – 0.05% of FS

Peak Efficiency: 90%

THD: 5%

Power Factor: 0.99

Current Rise Time (10-90): 30ms

Dimensions: 175″W x 50″D x 78″H | 350″W x 50″D x 78″H

[bs_well size=”sm”][/bs_well]

Overview

A member of the FTF High Power Packing and Testing System Family, the FTF-HV high voltage test system is capable of 1500V and 600 amps per channel with a maximum power capability of 450kW. These units are fully regenerative-powered with 92% efficiency, 0.05% current accuracy, and have 30 mSec risetime (10% to 90%) with zero overshoot for accurate laboratory battery testing.