Bitrode attends Westminster Abbey-Hosted 300 Years of Leadership and Innovation Event

Along with Bitrode, more than 700 guests gathered at Westminster Abbey’s Cloisters on Wednesday, 22 September 2021 to attend the official book launch of 300 Years of Leadership and Innovation. Bitrode is honored to be a select company featured in the official History of Parliament Trust 300 Years of Leadership and Innovation commemorative album, representing progress in battery power and sustainable energy.

Produced by the History of Parliament Trust – one of the most respected and authoritative research projects in British history – in partnership with leading publisher St James’s House and written by an editorial team of distinguished academics and award-winning authors, this beautifully designed, fully illustrated, 800-page publication has been produced to coincide with the

300th anniversary of the appointment of Britain’s first prime minister, Robert Walpole, in 1721, and in the year of Her Majesty The Queen’s 95th birthday.

Celebrating the best of British leadership, 300 Years of Leadership and Innovation features expertly written articles on those who have shaped British society, past and present; from Walpole to Cromwell, Churchill to Blair, The Queen and Prince Charles to captains of industry and innovation.

Bitrode’s Poster from NAATBatt

Bitrode attended the NAATBatt 2020 Annual Meeting and Conference last month in Pasadena, CA. This year, the show organizers asked that companies attending bring a poster-board display featuring equipment and services.

Take a look at Bitrode’s below:

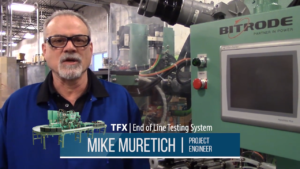

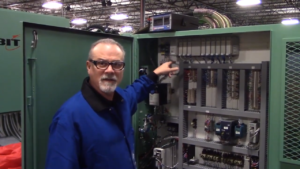

TFX Instructional Video

Bitrode presents our NEW Instructional Video on the TFX – End of the Line Testing Equipment.

Bitrode Project Engineer, Mike Muretich, teamed up with Marketing Specialist Brady Hardin to produce instructional videos. For the first video, Mike introduces contents of the two back cabinets:

https://www.youtube.com/watch?v=Pac5poHUGhQ&feature=youtu.be

In the next video, Mike will introduce the front controls. Stay in touch with our newsletter to be notified of future releases covering the front of the equipment and software operation.

More about the TFX:

High current discharge testing on the production line is a vital part of automotive and commercial battery manufacturing, and Bitrode’s model TFX is designed for just this task. The TFX combines the toughness required to operate reliably in the harsh environment of a battery facility with the most current networking and productivity tools, ensuring that testing can be smoothly integrated with production workflow and data across the entire manufacturing enterprise.

If you’d like to watching another video, go here to watch our 2019 review video:

COMING SOON: Instructional Videos on Bitrode’s TFX

[bs_lead]Project Manager Mike Muretich and Marketing Specialist Brady Hardin teamed up to create an upcoming series of instructional videos on Bitrode’s TFX – End of Line Testing System.[/bs_lead]The videos will feature Mike’s introduction to the equipment, plus a step-by-step guide to using key functions. They will include an introduction to the equipment’s parts, a demo on calibrating new batteries, switching between side-loading and top-loading battery end of line testing, and more.

To learn more about the specs and features of Bitrode’s TFX – End of Line Testing System, visit our website at https://www.bitrode.com/model-tfx.

If you’d prefer a .pdf to download or print, you’ll find a download link under the equipment’s title on the webpage (same for all our equipment webpages).

Stay connected with our newsletter or social media to be notified when the first of the series of video is released.

[bs_button size=”md” type=”info” value=”Newsletter Sign Up” href=”https://lp.constantcontact.com/su/pik0wAE/bitrodenews”] [bs_button size=”md” type=”info” value=”Facebook” href=”https://www.facebook.com/Bitrode/”] [bs_button size=”md” type=”info” value=”YouTube” href=”https://www.youtube.com/user/Bitrode”] [bs_button size=”md” type=”info” value=”Twitter” href=”https://twitter.com/bitrodecorp”]

Bitrode Employees Celebrate the Holidays

The Bitrode Headquarters, tucked away in a quiet industrial park in St. Louis, MO, isn’t used to visitors who are children. But things were very different one evening in December. Bitrode opened their doors for employees to invite their loved ones for a festive party and rare look behind-the-scenes look. Families filled the hallways, and even the shop was open to tour (safely, of course).

A photobooth, armed with props and festive borders, provided party-goers with mementos to carry away with them from the event. The CARE TEAM, the party’s organizers, planned special actives and crafts for the kids (and their grown-ups), designating one room each for decorating cookies and birdhouses.Bitrode provided food for everyone by way of two unique food trucks. There were Blues Fired Pizza (https://www.bluesfiredpizza.com/), which features a mobile brick oven custom-built into the truck, and Truck Norris (https://www.trucknorrisstl.com/), which specializes in comfort and classic foods with a twist. Everyone left the party very full and satisfied (especially with the cookies and desserts added).

The party was a huge success, and those who attended look forward to more in the future.

Special thank you the party’s organizers, The CARE TEAM. They are a group of volunteer employees organizing to take care of their co-workers inside and outside of the walls of Bitrode.

Bitrode Welder Creates Art

Bitrode welder, Joe Williams, wowed his co-workers by showing off his spray paint artwork. Soon, CEO Cyril Narishkin commissioned Williams to create more artwork featuring the St. Louis Arch and skyline to represent Bitrode’s hometown and headquarters.

Joe had mastered his art and was drawn to it as it combines his welding techniques and artistic talents. View more images of his work below.

Care Team Delivers Turkeys

The Bitrode Care Team exists to promote the company’s core principle of “taking care of our family in and out of these walls” by finding ways to help other. The team was created this year and wanted to do something meaningful to give back to the community for the Thanksgiving holiday. The team decided on partnering with a local church to provide turkeys for families in need. A donation box was set out, and Bitrode employees generously gave enough donations to provide 16 families with turkeys during Thanksgiving.

The Bitrode Care Team exists to promote the company’s core principle of “taking care of our family in and out of these walls” by finding ways to help other. The team was created this year and wanted to do something meaningful to give back to the community for the Thanksgiving holiday. The team decided on partnering with a local church to provide turkeys for families in need. A donation box was set out, and Bitrode employees generously gave enough donations to provide 16 families with turkeys during Thanksgiving.

And a special thank you to the employees who generously gave.

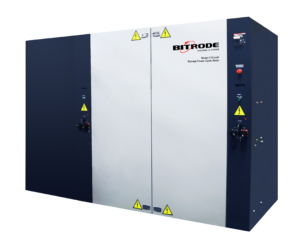

New FTF-HV Trade Ad

Catch a sneak peek of our new ad for the FTF-HV!

Our new ad is releasing soon in Charged Electric Vehicles Magazine, Batteries and Energy Storage Technology Magazine, Electric & Hybrid Vehicle Technology News, and other extraordinary trade publications.

The NEW FTF-HV features:

- Single or Dual Circuit Model Available

- Up to 600A/450KW Per Channel

- IGBT Design for 92% Efficiency

- 100% Duty Cycle Capable at Max Power

- Discharge Regenerative to the Grid

- 0.05% Current Accuracy with 30mSec Risetime and Zero Overshoot

- Test Control and Data Management with Bitrode’s VisuaLCNTM Lab Software

- Remote Binary Protocol Available for Control via 3rd Party Software

[bs_button size=”md” type=”info” value=”Learn More About the FTF-HV!” href=”https://www.bitrode.com/ftf-hv/”]

FTF Family for Laboratory Testing

Here are quick overviews of each model in the FTF Family:

FTF – Energy Storage Test System [FTF2 model also shown (dual FTFs side-by-side)]

The FTF is scalable to provide a maximum output power of 1.2MW. The FTF automated test system is designed to

provide continuous operation in high power applications where precise control of current and voltage is required.

General Specifications

Voltage: 35-500V / 40-700V / 58-1000V (Zero Volt optional)

Current: up to 1000A (4000A in parallel)

Circuits: up to 2

Network: Ethernet

Power: up to 300kW per cabinet; up to 1.2MW when using an external parallel controller

Accuracy: ±0.1% of FS*

Data Sampling Rate: 10ms (1ms optional)

Current Slew Rate: <4ms (10-90%) (dependent on cabinet specs)

Peak Efficiency: >92% (with typical 89-92)

FTF-HP High Power Energy Storage Test System [FTF2-HP model also shown (dual FTF-HPs side-by-side)]

The FTF-HP is one of the highest power test system in the market today. Scalable to provide a maximum output power of

4MW, the FTF-HP automated test system is designed to provide continuous operation in high power applications where

precise control of current and voltage is required.

General Specifications

Voltage: 33-500V / 40-700V / 58-1000V (Zero Volt optional)

Current: up to 1000A (4000A in parallel)

Power: 300KW to 1MW (700V max): Parallel operation: 4MW

300KW to 700KW (1000V max): Parallel operation 2.8MW

Accuracy: ±0.1% of FS*

Circuits: up to 2

Data Sampling Rate: 10ms (1ms optional)

Current Slew Rate: <10ms (10-90%)

Peak Efficiency: >92% (with typical 89 – 92)

FTF-HV High Voltage Pack Test System:

The newest member of the FTF High Power Packing and Testing System Family, the FTF-HV high voltage test system is capable of 1500V and 600 amps per channel with a maximum power capability of 450kW. These units are fully regenerative-powered with 92% efficiency, 0.05% current accuracy, and have 30 mSec risetime (10% to 90%) with zero overshoot for accurate laboratory battery testing.

General Specifications

Number of Circuits: 2 (Max 4)

Voltage Configurations: 100-1500VDC

Max Current: 600/1200A | 1200/2400A

Max Power: 450KW | 900KW

Accuracy: Voltage – 0.1% of FS | Current – 0.05% of FS

Peak Efficiency: 90%

THD: 5%

Power Factor: 0.99

Current Rise Time (10-90): 30ms

Dimensions: 175″W x 50″D x 78″H | 350″W x 50″D x 78″H

FTF Family Models Additional Key Features:

- FTF Family models are configurable for testing to industry standards such as IEC, SAE, BCI and drive simulations for FUDS, SFUDS, GSFUDS, DST and ECE-15L

- All FTF Family models operate on Bitrode’s VisuaLCNᵀᴹ Software designed for laboratories

- No performance loss under voltage control

- Quick disconnects on output leads

[bs_button size=”md” type=”info” value=”Learn More About Lab Testing Equipment Options” href=”https://www.bitrode.com/products/lab/”]

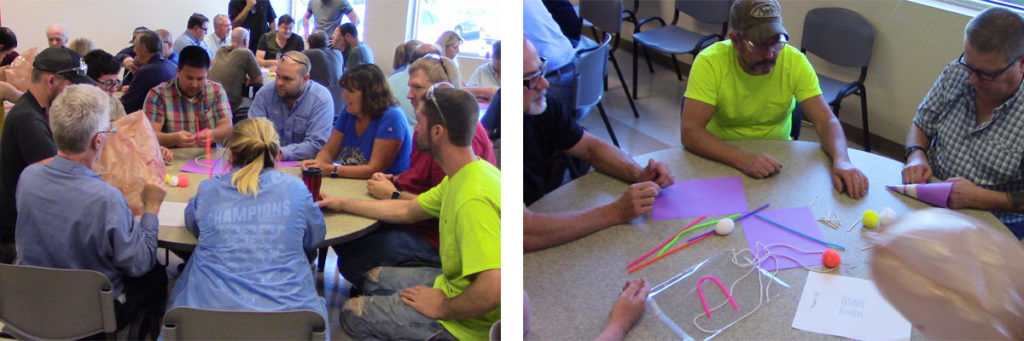

Egg Drop Team Building

It’s typical for employees to be unfamiliar with members of other department within their company, but Bitrode is creating a different culture.

From engineering to production, the Bitrode headquarters in St. Louis, MO is home to many, interconnected departments. To build teamwork and familiarity between disciplines, employees participated in a company-wide egg drop competition.

Representatives from each department (engineering, admin, production, sale/marketing) made up the teams. Together, they designed and created competing contraptions to house an egg so it will survive a drop uncracked. Each team built from a bag of materials, such as tape, string, pipe cleaners, tongue depressors, etc. For 10 short minutes, teams combined their strengths to create the best contraption possible.

After completing the egg-protecting apparatuses, they were dropped from 10 feet. If the egg survived, they moved to next rounds which included 15 and 20 feet drops.

Out of the 12 teams, 5 survived the 20 feet drop and battled for the winning title in an tie-breaking egg toss competition. 2 from each team tossed their egg to one another at increasing distances until only one team survived.

Employees agreed that the event was a success and helped build comradery. Marketing specialist Brady Hardin said, “It’s a net positive to know the people behind the polite smiles you see in the hallways or in the emails. Sure we were building a little thing to save an egg, but we also built teams.”

Due to its success in bringing people together, Bitrode plans to hold the Egg Drop competition again in the future.